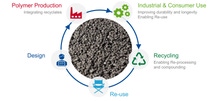

- Brand owners to achieve their circular economy and sustainability targets

- Plastic converters to incorporate more recycled content

- Mechanical recyclers to improve recyclate quality and processability

Enhancing

ENHANCE the circularity of plastics

ENHANCE the circularity of plastics with IrgaCycle® additive solutions designed for the mechanical recycling process

After the washing stage, the dried flakes are fed into an extruder where they are melted for further processing. During this process plastic polymers are susceptible to oxidative and thermal degradation. At this stage the physical properties of the plastic can be enhanced by the use of specialized additives.

After Sorting and Washing the Plastics should be enhanced

Rejuvenating recycled plastics with IrgaCycle® additive solutions

Virgin plastic polymers are primarily designed and stabilized for a single lifecycle. Mechanically recycling polyolefin plastics can generate a number of issues with the material performance including impurities, gel formation, mechanical weaknesses, and melt-flow fluctuations. IrgaCycle® additive solutions are specifically tailored for to address these challenges and yield a higher quality recyclate.